For the production of Crude glycerine at 80 - 88% concentration starting from purified Soap Spent Lyes or Sweet Waters. Concentration is obtained by evaporation of water: CGE is a double effect plant with thermo-compression including the most recent innovations that, permitting substantial steam savings, are a decisive factor for reduced manufacturing costs.

When Soap Spent Lyes are concentrated, the presence of NaCl makes this operation very delicate and it is at this moment that the Binacchi experience makes the difference. In fact the selection of construction materials becomes essential to reduce corrosion problems. Also a good transport of a viscous slurry made up by salt and glycerine is crucial, otherwise blockages of pipes will frequently occur.

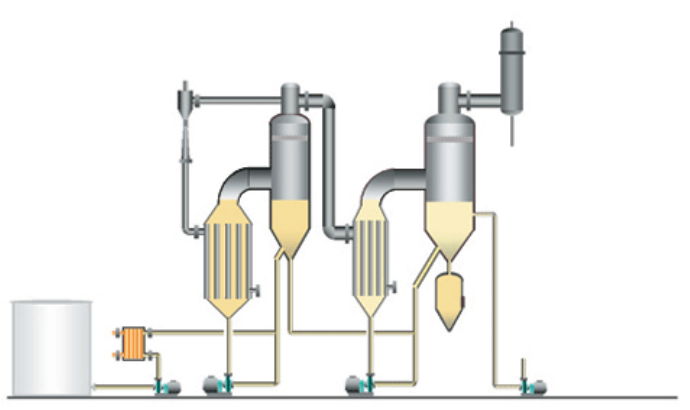

The treated feedstock is continuously and automatically evaporated to 80 - 88% crude glycerine and salt is recovered by precipitation (in case of Soap Spent Lyes). Evaporation in the first effect is by steam and by a part of vapours generated in the first evaporation chamber that are sucked and recompressed by a thermo-compressor. While the rest of them flows into the heat exchanger shell of the second effect, making the liquid inside boiling thanks to the effect of vacuum. In the second effect glycerine reaches 80 - 88% concentration.