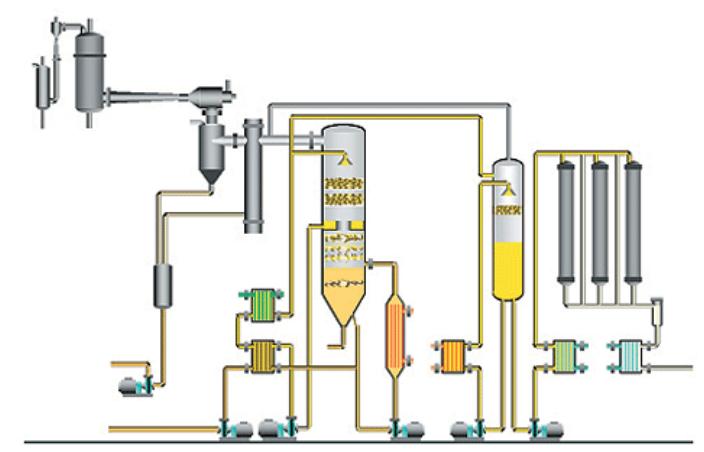

Binacchi GDN distillation plants refine Crude Glycerine into high quality Pharmaceutical - Food Grade Distilled Glycerol, in accordance with the most important specifications like British Standard; USP U.S. Pharmacopoeia Standard; Codex; etc.

In the main distillation column, glycerol and water are vaporised while inorganic and organic impurities settle at its bottom, from where they are extracted. Glycerol and water vapours are cleaned from entrained impurities and then glycerol vapours are condensed in order to obtain very pure distilled glycerine.

A big advantage of GDN distillations is that the various process stages do not involve the use of very tall columns, hence avoiding high building costs as well as uncomfortable plant operation.

Now glycerine is sent to the deodorizer to strip off odoriferous materials and finally it is bleached with activated carbons.

Distillation residues (foots) are processed to recover the glycerol they contain. Binacchi offers you a choice between various systems. Among them there is the exclusive Wiped Film Evaporator, expressly designed and manufactured by Binacchi for glycerine operation in order to offer you high glycerol recovery rates as well as reduced operating costs. Its design is the evolution of many Wiped Film Evaporators put in operation in the past and from the wide experience gained with them